This is the second blogpost of Ilo Nanpa. You can read the first blogpost here: Ilo Nanpa (Toki Pona Calculator) - Release Announcement and Technical Details

Hey guys! I'll be distributing new units of ilo nanpa! Previously, ilo nanpa was distributed in irregular batches. From now on, I'll be shipping a batch at approximately the end of each month (unless I run out of stock).

With time-efficient production method, the time-cost of unit production is reduced by quite a lot. Therefore, I'm lowering the average donation target per unit from $30 to $20 for all of the new units produced, including international shipping fee.

For each donation made, I'd add the amount to the donation pool. For each unit shipped, I'd deduct $20 from the pool. The fund available in the donation pool will be used for giveaways, or for subsidizing those who're donating less.

For a donation of $25 per unit or above, you'll be enlisted as one of the honored donors in the official website of ilo nanpa.

If you're interested, here's the procedure of getting a unit of ilo nanpa:

If you wish to add funds to the donation pool without getting a unit of ilo nanpa, just donate to me using the donate button in the homepage of my website and contact me. The donation will be 100% used for subsidizing the recipients who are donating less or not donating (i.e. giveaway). If you wish to be named, a donation of $5 would enlist you as one of the honored donors.

The official website of ilo nanpa has been updated to show the number of units in stock, units distributed and the amount of fund available in the donation pool.

Here's the breakdown of the spending of donation for each unit:

I'd like to take this opportunity to thank all of the previous donors. With the donated amount, I've purchased new equipment, which allows me to produce ilo nanpa more efficiently.

As I'm rather new in electronics world, my current technical ability of assembling electronic parts is rather rudimentary. I've been assembling electronic devices by soldering the components onto the PCB using soldering iron one-by-one, which is extremely time consuming.

Before this project, I only had to assemble one, or perhaps a couple of prototype units for my projects. So the time inefficiency wasn't an issue. However, this had changed since the completion of the ilo napna project. I have to manually solder a handful of units of the device in order to distribute them to Toki Pona speakers. And it took me two hours to produce a unit of the device, which was dog slow. And the demand just isn't high enough to justify outsourcing the assembly process.

As the previous production method was time consuming, I looked into more time-efficient production alternatives. After some Google-Fu, I've found that solder paste stencil-based soldering is probably the way to go for the following reasons:

I've purchased the following equipment and material for experimenting with this production method:

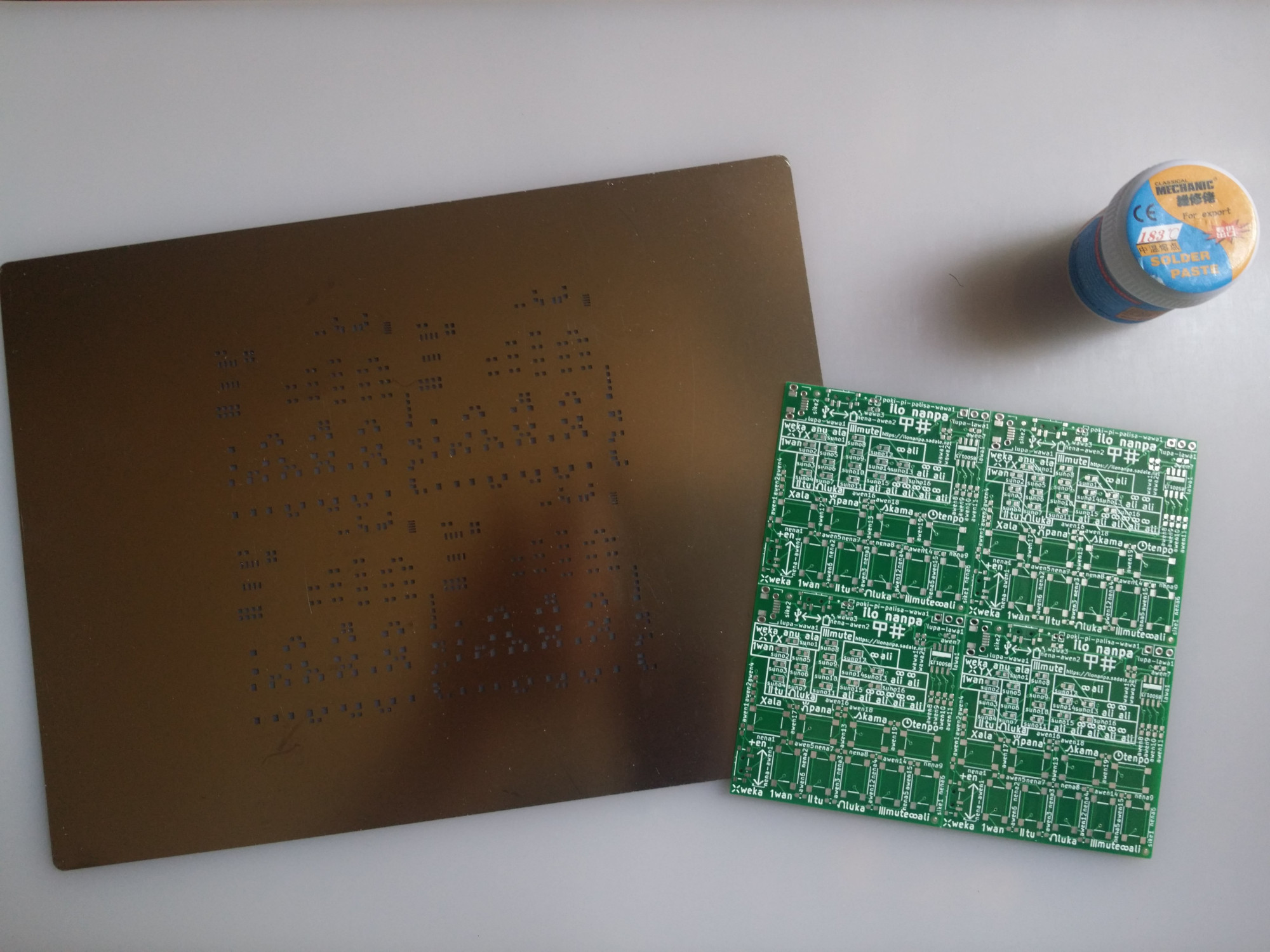

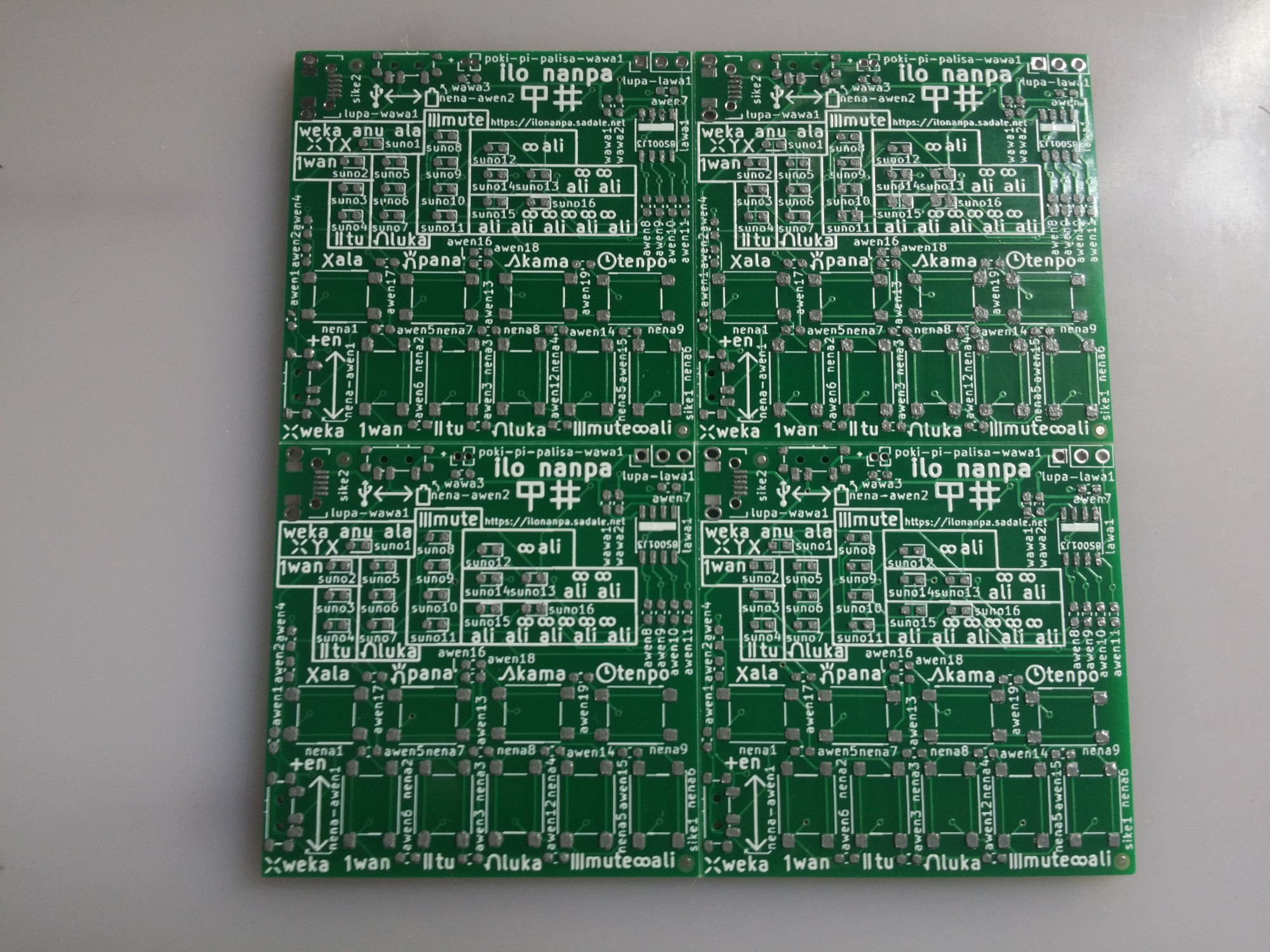

I've purchased a new batch of ilo nanpa boards. This time, the boards are panelized so that four units of the device can be produced for each PCB. After soldering them, I'd break up the PCB and I'll get four devices from a board. Here's the photo showing a jar of solder paste, panelized PCB and a stencil on a heat-resistant mat:

Not all components can be soldered by this technique. Only SMD components can be soldered in this way. Fortunately, most of the components of ilo nanpa are SMD components. The only components that require using soldering iron are the USB port, programming port and the battery holder.

I mostly just followed this solder stencil tutorial on Youtube. Except that I'm using hot air gun instead of reflow skillet for soldering the components onto the PCB.

Here's how I'm producing the devices using this new production method:

In step 2, since some spare PCBs are required for using the stencil, the 10 thought-to-be-useless wrong ilo musi boards that I ordered long time ago is now somehow useful. They're perfect to be used for holding the ilo nanpa PCB workpiece in place so that I can apply solder paste using the stencil easily.

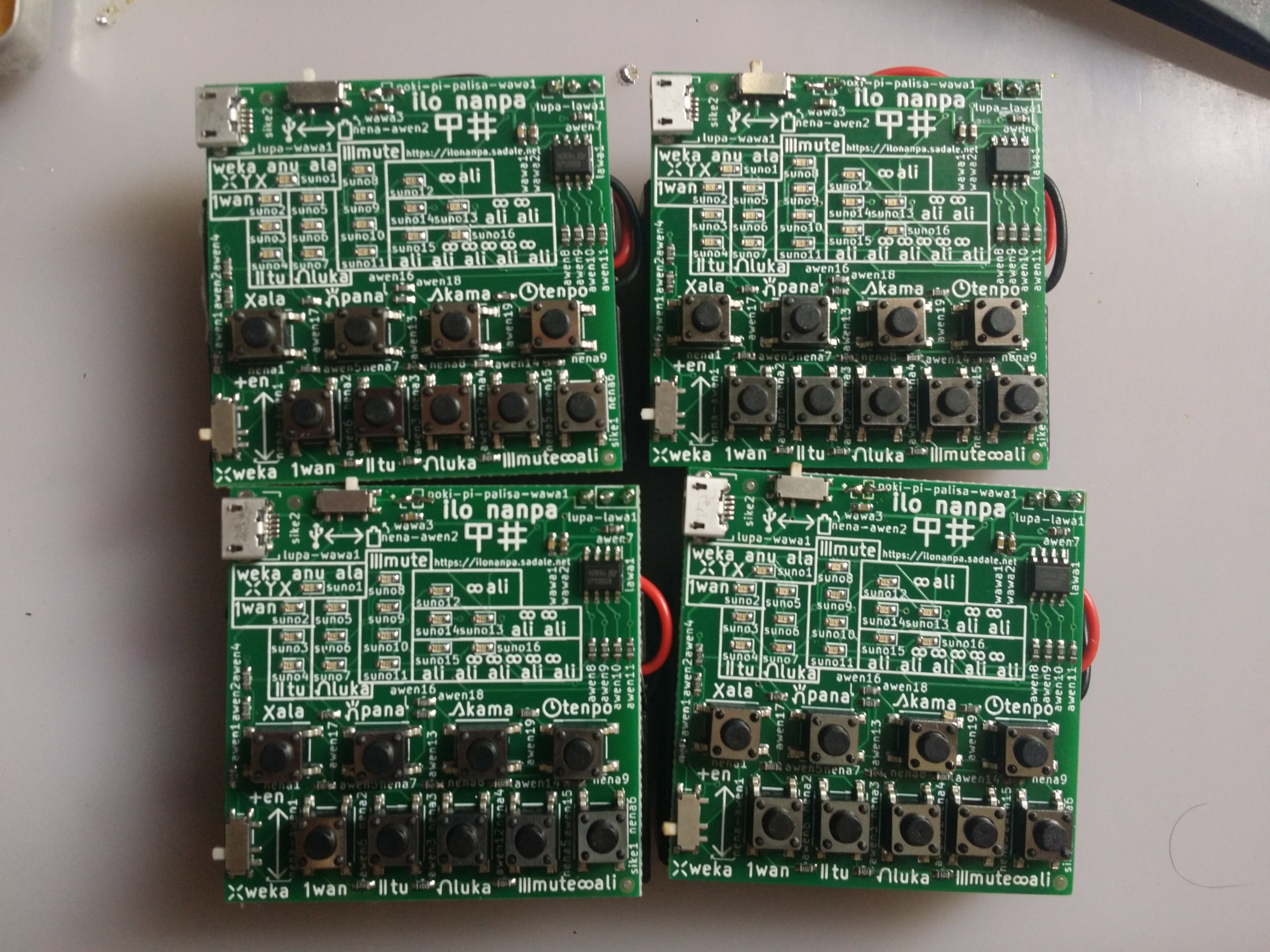

At the end of step 3, here's a photo showing a work-in-progress panelized PCB. Take a close look and you'll see there's a layer of gray solder paste applied on each of its pads:

As for the hot air gun in step 5, it's empirically found that setting the air flow to 2/8 and the temperature to 3/8 works well for soldering the components.

This new production method works very well. Despite that the stencil is a bit expensive, it has cut down the production time by quite a lot. Before using this method, I produced ilo nanpa at a rate of a unit per two hours. After using this method, I managed to produce four units within 2.5 hours, with an additional 0.5 hours of setup and cleanup time.

This production method is very helpful for producing several units of electronic devices in timely manner. For a demand of 20-ish units, it seems to me that it's the go-to method for production. I'm very glad to have learned it. I'll continue be using this method for small scale production.

toki!

o pona a!

pali ona en lipu ona li pona mute mute!

mi pilin e ona li sona mute mute!

tenpo kama lili la mi en ona li ken toki la pona a!

mi tawa!